- 38

- 842 852

Antalz

Netherlands

Приєднався 18 жов 2006

I make videos on science and technology. This includes scientific experiments, demonstrations of scientific or technological principles, and construction of scientific experiments and other contraptions. If you have any suggestions for topics I should cover, let me know.

Thanks,

Antal

Thanks,

Antal

3D Printed Cages for Silica Desiccant

@MihaiDesigns recently uploaded a short video where he shows a small cage to contain desiccant, and then he puts a few of those inside of a dryfeeder that he's working on. I really liked that idea, and I wondered if you can dry the desiccant while it's still inside the cage. It turns out the silica dries fine at 80C in a food dehydrator, where the usual recomendation is 120C in the oven. I'm not sure if an oven would work with these cages, I guess if you print them in polycarbonate it would work.

Mihai’s video: ua-cam.com/video/5FZSqb4dyDM/v-deo.html

Relevent Reddit thread: www.reddit.com/r/3Dprinting/comments/n5n7tg/using_gyroid_infill_as_walls_i_redesigned_my/

See more of my work here:

Instagram: creo_nova

Website: www.creonova.nl/

Mihai’s video: ua-cam.com/video/5FZSqb4dyDM/v-deo.html

Relevent Reddit thread: www.reddit.com/r/3Dprinting/comments/n5n7tg/using_gyroid_infill_as_walls_i_redesigned_my/

See more of my work here:

Instagram: creo_nova

Website: www.creonova.nl/

Переглядів: 2 561

Відео

Fusion360 Assembly Tutorial; Full practical assembly from scratch

Переглядів 101 тис.3 роки тому

Today we'll create a full assembly from scratch, how to set up (sub)components, different joint techniques, appearances, motion links, joint limits, rigid groups, contact sets, and much more. You can find more about project PolyVent here: covid-eic.easme-web.eu/solution/polyvent-global-ventilator-design-formula/about See more of my work here: Instagram: creo_nova Website: www.cre...

The Physics of why your 3D Prints Warp, and what to do about it

Переглядів 6 тис.3 роки тому

Warping and delamination are recurring problems in FDM 3D printing for higher temperature materials such as ABS, Polycarbonate, Nylon, PEI and PEEK. Here I show a basic physics model to help understand what exactly causes warping, and based on that what you can do about it. It also explains why Polycarbonate warps much more than PLA, even though their coefficients of thermal expansion are nearl...

How to Replace Gears and Reverse Engineer Sprockets

Переглядів 2,4 тис.3 роки тому

Replacing a broken gear is a question I've seen come up a few times, so here I show how to figure out the numbers you need to buy or make a replacement. Next I'll show you how to reverse engineer sprockets and exotic gears by tracing a scanned image or photograph of the part. PDF with preferred values: www.sdp-si.com/D805/D805_PDFS/Technical/8050T017.pdf Find more of my work here: Instagram: in...

How to model Worm Gears (Gears pt 7/?)

Переглядів 38 тис.3 роки тому

In this episode we're taking a look at how to model worm gears in Fusion360 for 3D printing. You can use these to transfer power between non-intersecting shafts, and with high gear ratios in a compact package. Primary downside is the low efficiency, and the resulting wear and heat buildup. In this presentation I show worm gears as a rack twisted into a helix, but you can also regard worm gears ...

Medicine delivery robot Proof of Concept

Переглядів 1 тис.3 роки тому

Many diseases and injuries make a patient immobile, such as broken legs, spinal chord injuries, or Parkinson's. Because of this patients are unable to move around to get medication and water on their own. For bedridden patients you could stack supplies next to the bed, but only up to a point, and Parkinson's patients could be anywhere when they stiffen up. For this demonstration I'm controlling...

PLA Filament Datasheets are often wrong

Переглядів 8153 роки тому

Many PLA vendors will give you a datasheet, and while most of them claim their filament to be special due to 11 herbs and spices, they simply copied their material properties from Natureworks LLC, from whom they got their resin. Next problem: they copied the wrong datasheet. I want to stress that even if the values are correct for the base filament, they're still useless and misleading because ...

How to model Bevel Gears using Tredgold's Approximation (Gears pt 6/7)

Переглядів 54 тис.3 роки тому

Here I show how you can model a set of bevel gears in Fusion360 for 3D printing. I'm using Tredgold's approximation to obtain tooth profiles, which is one of a few techniques. Another well-known one is the gleason system. True spherical involutes are used very rarely. Files created in this video can be found here: www.thingiverse.com/thing:4927350 Instagram: creo_nova Website: ww...

How to power Raspberry Pi and Arduino from LiPo batteries

Переглядів 26 тис.3 роки тому

In most robot projects you'll have a battery to power the motors and actuators. You also need a controller, where Raspberry Pi and Arduino are convenient and powerful options. In this video I show how you can power that controller from the LiPo battery. In the first part I cover various parts you can use to generate 5 volts. Next I cover some parts and techniques to deliver 5V into the board. 0...

How to add Analog Inputs to your Raspberry Pi using MCP3008/3208

Переглядів 13 тис.3 роки тому

Raspberry Pis don't have analong inputs out of the box, unlike Arduinos, so here I show how to add them using the MCP chip family. Code: creonovae-my.sharepoint.com/:f:/g/personal/antal_creonova_nl/ErfMfqH786ZDt6pXKnq8bkYBmlK7-yREYguUf6RstdRYAw?e=pCBerH Code inspired by: www.raspberrypi-spy.co.uk/2013/10/analogue-sensors-on-the-raspberry-pi-using-an-mcp3008/ When using pigpio, don't forget to s...

How to model Planetary Gears; Requirements, Gear Ratios, Helical/Herringbone (Gears pt 5/7)

Переглядів 93 тис.3 роки тому

I show how to model a ring gear, how to set up planets, carrier and sun, joints and motion links, and making helical/herringbone sets. I'm using Fusion360, though it should work fine in other CAD software, and I 3D print the set to show you that it works. Files: www.thingiverse.com/thing:4655373 Playlist with all my gear tutorials: ua-cam.com/play/PL4Yme23PQa9njUgvH2o2HP03-4RtZObzO.html Further...

Rebuilding my WASD-controlled tank

Переглядів 2,2 тис.3 роки тому

Over two months after completing those drive units I finally put them in the tank, fix up the electronics, and make this thing drive. You can find more of my work here: creo_nova www.creonova.nl/

Short channel update (Oct 2020)

Переглядів 7583 роки тому

I haven't uploaded anything in a long while now, so I wanted to take a minute to explain what's been happening and what will be happening in the near future. You can also find me here: creo_nova www.creonova.nl/ Here are some articles written about the PolyVent Linz prototype: ooe.orf.at/stories/3071365/ www.sn.at/panorama/wissen/polyvent-baute-in-linz-den-prototyp-eines-beatmung...

How to model Gear Racks, Straight and Helical, Parametric (Gears pt 4/7)

Переглядів 34 тис.3 роки тому

In this video I show how to model a gear rack in Fusion360, though the method translates easily to any other CAD package. Topics covered: 0:00 Introduction and setting up parameters 1:27 Sketching the tooth profile 5:08 Patterning the tooth to make a rack 6:12 Modifying rack by changing parameters 6:50 Adding backlash to the rack 7:43 Making a Helical Rack 9:08 Looking at Transverse vs Normal m...

Portable Air Conditioner Hose through outward tilting Casement Window

Переглядів 45 тис.3 роки тому

We had a pretty significant heatwave here in the Netherlands recently, so I finally got myself a portable air conditioning unit. These units blow hot air out of a duct, which you must lead out of the house. Doing this with a sliding window that's pretty easy, but with a tilting window it's a bit more complicated, even more so when the window tilts outwards. In this video I show you a system I c...

Work faster and more accurately using simple 3D printed jigs

Переглядів 1 тис.3 роки тому

Work faster and more accurately using simple 3D printed jigs

How to model Helical and Herringbone Gears; pros and cons (Gears pt 3/7)

Переглядів 40 тис.3 роки тому

How to model Helical and Herringbone Gears; pros and cons (Gears pt 3/7)

Assembling the Right Side Drive Unit for my Remote Controlled Tank

Переглядів 1,6 тис.3 роки тому

Assembling the Right Side Drive Unit for my Remote Controlled Tank

Ventilator 3D printed bellows showcase

Переглядів 8023 роки тому

Ventilator 3D printed bellows showcase

OpenVent B1 ventilator design walkthrough

Переглядів 5603 роки тому

OpenVent B1 ventilator design walkthrough

Bellows-based ventilator working for the first time

Переглядів 3993 роки тому

Bellows-based ventilator working for the first time

Emergency ventilator update - Pump works

Переглядів 3394 роки тому

Emergency ventilator update - Pump works

Progress update on piston-pump emergency ventilator design

Переглядів 9904 роки тому

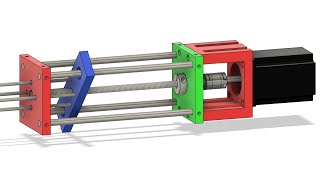

Progress update on piston-pump emergency ventilator design

Improved jig to drill holes through shafts, to attach gears/pulleys/wheels/sprockets

Переглядів 3,5 тис.4 роки тому

Improved jig to drill holes through shafts, to attach gears/pulleys/wheels/sprockets

How to build an Overhead Camera Rig for DSLRs for under 30€ using minimal tools

Переглядів 3684 роки тому

How to build an Overhead Camera Rig for DSLRs for under 30€ using minimal tools

Bruce Yeany's Centrifuge Toy 3D printed

Переглядів 4714 роки тому

Bruce Yeany's Centrifuge Toy 3D printed

Showing Light is a Wave using a Dirty Mirror

Переглядів 3544 роки тому

Showing Light is a Wave using a Dirty Mirror

The difference between Static and Dynamic Unbalance

Переглядів 27 тис.4 роки тому

The difference between Static and Dynamic Unbalance

Gear Parameters and Design Tradeoffs (Gears pt 2/7)

Переглядів 43 тис.4 роки тому

Gear Parameters and Design Tradeoffs (Gears pt 2/7)

How to model compound gears, and how to chamfer the teeth of gears. (Gears pt 1.5/7)

Переглядів 17 тис.4 роки тому

How to model compound gears, and how to chamfer the teeth of gears. (Gears pt 1.5/7)

That’s genius!

Get a bambu

half the control board and double stack it right at the back? it looks like a heavy piece of MDF. Have you considered Carbon FIber? :D I hear LED's make things to faster also.

How do you find out about cool things like this?

I found out about this one from the "Mechanics of metamaterials" course at the Leiden University physics department when I was doing my master's there. Martin van Hecke's taught that course, and his research group published some more stuff you might be interested in. I also know Ron Resch had a bunch of other stuff that was really cool.

@@antalz Cool. Thanks!

great topic, thanks 👍

You're a genius thank you

Thanks a lot for that mate!

This is the tutorial I have been wanting all along! I really appreciate your scaffolded approach, presenting material in increasing difficulty rather than overwhelming a beginner with everything at once. You've given a lot to think about, but you've supplied the tools to perform the analyses. I can't wait to see your videos on herringbone and helical gears. Thank you!

GOAT

Bro plz make more videos like this it was really helpful. Thank you ❤😊

기계원리를 만드는 과정이 힘들었지만 아뭊든 영상 잘보고 갑니다

Just now seeing this. You did a fantastic job. I don't think I've ever heard such a clear explanation of a mechanical system.

Wow. Amazing tutorial. You have such a great way of explaining things. Thank you so much!!!

unreal editor 2.0 tutorial: Lesson 2 when?????

I'm afraid never. I'm curious though, what are you using UnrealED 2.0 for in 2024?

@@antalz postal 2 custom maps postal 2 uses unreal engine 2 i need help adding sky box and cutscenes with npc spawners

17:53 기어의 압력각에 따른 힘의 방향 설명

Amazing. Thank you for this helpful video

did an entire mechanical engineering degree and not once was this demonstrated. it makes sense when you look at the math but noone ever demos

I remember a demo in my classical mechanics class in my physics major, that helped a lot.

Perfect Job!

24:13 I was following the exact same steps as you narrated here, but my lower shaft collar was still not spinning with the lead screw. Please help.

Extremely good video. Top Notch! Thank you.

Excelent video thanks. If you hollow the large gear it might just be possible to mount another bearing inside it between the gear and the shaft.

That's actually a very interesting idea, though it does appear to me assembly could get tricky.

very interesting video, i dont have a 3d printer but might ask somebody to print the handles for me, im dreading summer XD

You can also make the latches entirely from wood, primarily using dowel rod you can buy from the hardware store. I had wanted to make an update video showing that, but I never got around to it.

Great video! Thanks for showing us your idea!

Incredibly useful video that I have found after 2 years with Fusion 360. I love your lessons, man! Thank you very much!

Thank you so much for this tutorial video. I appreciate your effort!

I have a question for the addendum why did you subtract (1*module) from the root diameter

Loved the video it was very detailed and easy to follow

How Can I like this video 10 times?

im here from Unreal 5.4 🙂

This is weird but i was printing a 3dbenchy and encountered a problem I've had for a while now. My set up is a 0.4mm nozzle ender 3 printing PETG mostly at a bed temp of 85~90C cause i find it gives better bed adhesion, and the issue is that on certain prints I would get this absolutely horrendous warping ~6-8mm above the build plate. Any sort of corner would just begin to curl up and inwards on itself, and I tried everything suggested in this vid short of using an enclosure. I even slowed prints all the way to 25% and i still get this warping. Curiously, it seems to happen only for thinner layer heights, when i bump it up to 0.24 and above, this problem reduces or goes away entirely, but thats obviously not a good fix for the problem. i don't have this problem on my much faster klipper printer either, regardless of the layer height at the same bed temps. I read something in a comment on another video, which was to lower bed temp, i tried it, lowering to 72C and that reduced my warping by a lot. Whats the explanation for this? Obviously closer to the bed, the high temp reduces warpage, and at a certain height, the warping would initiate due to the lower temperature, but why does it diminish when i use a lower bed temp from the start, very fast print speed or thicker layers?

If top layers cool faster it will pull the edges upwards and inwards. Solution I found was to not use the part cooler unless printing overhangs

The effect dimishes when you lower bed temp as it reduces the difference in heat between the lower layer on the bed and the upper layers cooling faster as they build up from the base.

Guys please anybody can send that rack and pinion which is completely done in autodesk link 🙏please

I wish I came to watch a video like this before I fried my circuits 😑

goat

Quick update from the future: Formfutura has updated it! formfutura.com/datasheets/formfutura-tds-reformrpla.pdf

The exponential temperature decay is due to the nature of thermal energy transfer being proportional to the temperature via W/m·K, not because of your explanation.

Thanks for the clear explanation. Can you please clarify why printing slower would make a difference? Assuming the ambient, nozzle, and bed temperatures are the same, printing slower would still yield the same temperatures all around, no? If anything it would start laying down the next layer sooner before the previous cools down more.

By printing slower the plastic flowing through the nozzle has more time to actually get up to the nozzle temperature, if you print fast the plastic comes out slightly colder due to limited thermal conduction inside of the plastic itself.

@@antalz that is an excellent point! Thank you for the response.

i was trying to redefine the plane from this time line, 13:26 but i got a warning sign and the sketch was not redefines. can u help me to resolve this please

Great explanqtion, thank you! A follow-up video where you explain the effect of bed heating would be awesome.

Thanks so much for this video . From where did get these latches ?

The latches are 3D printed, there's a link in the description to the files

Nice and detailed

Fusion isn’t letting me select the push pull and extrude together

I don't understand, Extrude and push/pull are two different commands so you shouldn't need to use them simultaneously. What part of the video is this?

Really your lecture excellant on this subject thanque

This was such a refreshing tutorial, where it was challenging yet doable at the same time coupled with your guidance throughout the video, perfect! I learned so much and gained valuable experience on how to put together an assembly. Btw this was my first time attempt at assembly and I'm happy to say I nailed it!

That's great to hear, happy modeling!

If there is 2 sun gears with 2 shafts ouputs. Rotateing in different directions with same speed. Can you do it?

I believe not, not if both suns are connected to the planets. Because if the planets spin in one direction, both suns must turn in the opposite direction.

@@antalz yes, I agree with you. But in the case I am asking. Every sun gear is commented with planetary gear. Because it has 2 set of planetaries gear. However, the 2 set of planetaries gear are connected together.

Really great video! The video answered a lot of questions I've had around assemblies and joints and just general workflow. Thanks for taking the time to put these together!

I realise you published this ages ago, but still wanted you to know. between this and your worm gear video (the only two I have watched so far), I have learnt far more about fusion 360 than I have in the past 5 years of hobby use. That's despite watching a number of other tutorials and countless hours or googling.

Thanks, that's still encouraging to hear!

I've also just come across this video, and now I intend to devour all the other videos of yours.

Thank you for the math that reinforces what we all think occurs. Running primarily ABS, it was a must to have an enclosure and running higher bed temps. I'm running 250c on the nozzle and 125c on the bed (Creality CR10s-300) currently with outstanding results just incase someone else is looking at the same setup~

Cannot seem to redefine the sketch plane at step 13:25 successfully to flip the hole to the top of the part. No matter, what I do the large hole remains on the bottom of the Bottom Plate. I go through all the supposed steps of selecting the sketch, going to the Timeline, right clicking and selecting Redefine Sketch Plane, selecting the top of the Top Plane and nothing happens.

It appears several people got this issue. Can you delete the sketch from the timeline for the copied component and then create a correct sketch on the right side so you can continue?

I really appreciate these videos with your practical applications to real world situations. Having farmed in the midwest US for many years I sometimes applied the same techniques (such as shortening a bolt, or using a screw driver as a punch) in our farm "shop". At this time however I especially appreciate the Fusion techniques you're showing as I am quite a novice in this CAD program.

one of the most useful videos i have seen for what i specifically need Thank you!

W video